Tools

Tools

Getting the right tool can make the difference between an OK conversion and a great conversion.

You do need some tools and a workspace but you don't need every electrical tool in B&Q.

You Need a Workspace

Your workspace is somewhere that you can leave a part half done as it is time for bed or make lots of noise drilling and sawing. It can be part of a garage or a bespoke workshop. I spent several weeks cleaning out my garage and building my own 6 ft work benches so that I had space to work and place different pieces of machinery.

I also installed extra lighting so that it was a pleasant place to work. Being a garage, I could open the end door to get fresh air and sunlight in during the summer.

One of the most important bits of kit I bought for my workshop was a cyclone to build a dust extraction system. I got the plastic cyclone , some vacuum hose and a large 60L barrel as my dust collector. You attach a vacuum cleaner to the top and the side outlet can suck up all the dust you will make. The cyclone will separate about 90-95% of the wood dust and stop your vacuum cleaner bag from filling up in 2 minutes. I changed the vacuum cleaner bag twice in 12 months and emptied the 60L drum twice.

I attach the hose to the table saw, mitre saw and all the hand-held power tools. It is also good for cleaning the bench and floor.

I bought 2 expensive power tools to help me in the building of all the wooden parts.

The first is a Mitre saw. I went for the Evolution R255 SMS as I didn't want to spend a fortune and I'm only a casual DIYer. I found it great for repeat cuts with a simple clamped stop on the bench. I built a table for it that made the side benches the same height as the cutting surface. This gave me enough room to cut 2.4m lengths of timber.

I only needed the single bevel to cut compound angles.

The second investment buy was a table saw.

After watching many videos, I again came to the conclusion that I could not justify spending £500+ on a branded model. So, I went for what seems to be a fairly generic version. I found what looks like the identical saw being sold under many brands. It is also the one that Greg Virgoe uses.

It has a fence that is clamped at both ends so you get a solid edge to push the wood against.

I used this tool the most and was well worth the cost. During lockdown the supply of cut timber became very difficult. Getting the correct size timber was not possible but with the table saw I was able to make my own 44x18 and 34x34 sections with lengths up to 2.4m long. The finish was as a good as planned.

Some Useful Tools

These are a few of the tools that I found most useful in building the van.

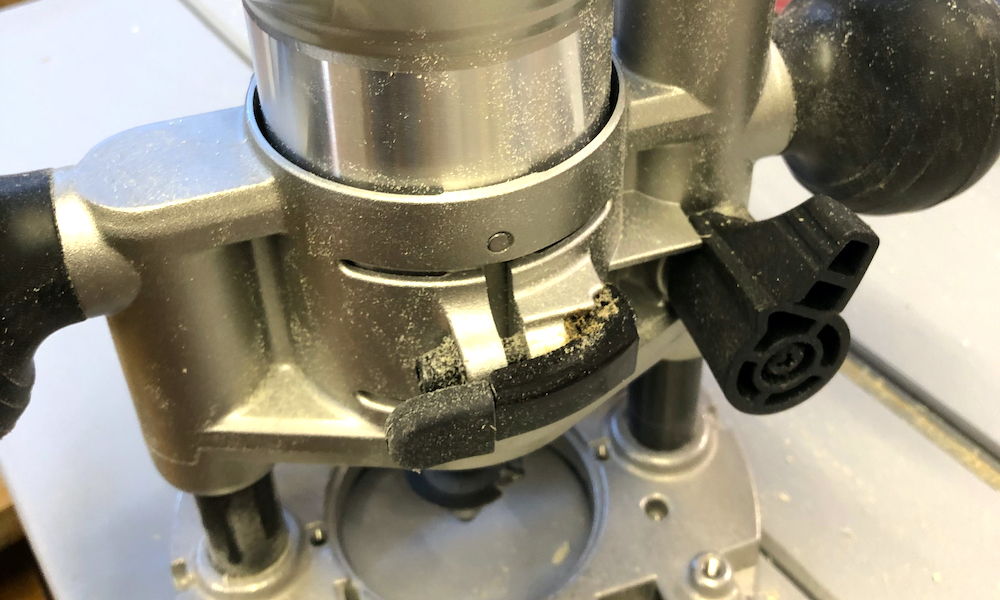

A Makita RT0700C palm router with a plunger adapter and hand-held collar. This was very useful in cutting out the cladding around the vents and the edges of the ply-wood to get a good flush finish. It was also good and putting a chamfer or radius on different pieces.

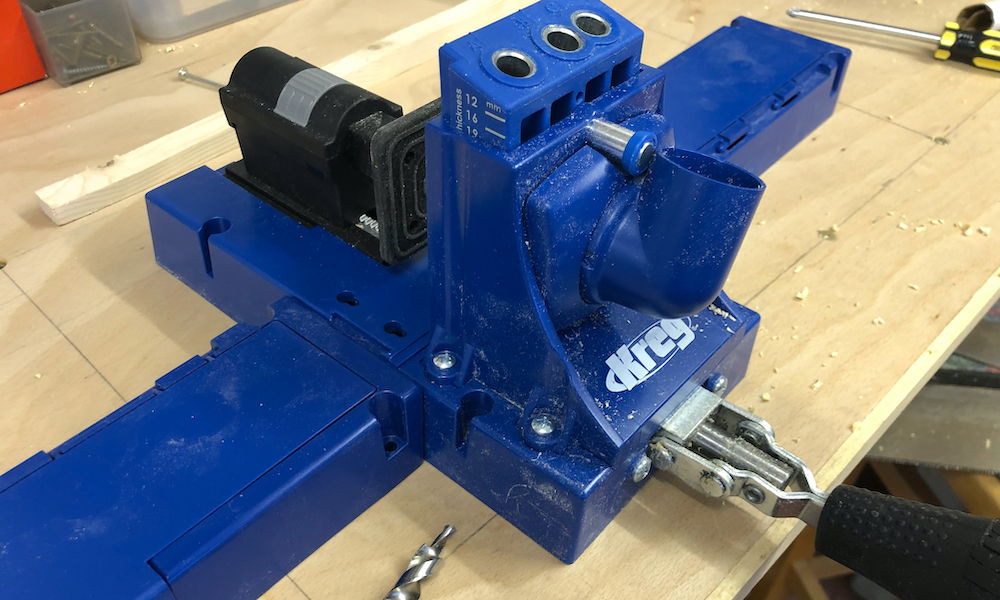

A tool that I had never personally used but have wonder why I didn't buy one before was the pocket screw jig. I bought the expensive one (Kreg K5) but I did change to cheaper screws without noticing much difference. The fact that you can create a hidden joint without having to use metal brackets or time consuming wooden joints was a blessing for this project. You can select the thickness of wood you are drilling into and set the stepped drill bit to the correct depth. The square head drive does get a bit of use to but it works well with a torque adjustable electric drill.

It is designed to be fixed to a bench but I used clamps without any issues. One problem is that the screws have either a fine or coarse pitch to self-cut into the wood. It is stated that fine is for hardwood and coarse for softwood but I found that if the wood is not very thick (less than 18mm) or the screws are close together then the coarse thread theds to lead to the wood splitting. I started using the fine pitch when I though splitting could be an issue.

I bought a few tools at the start that I thought would help. One of the best was a set of corner clamps for frame making. These were used from making the window frames and used a lot when I was building the carcasses for the drawers. They helped hold everything square while I screwed in the pocket screws.

A tool I bought as putting in rivnuts is impossible without it. This was a threaded nut riveter. The only one I found that wasn't extremely costly was the Sealey short arm. This states it can do up to M12 but I think you need to be a body builder to use it on anything above an M8 insert.

I used this for lots of M5, M6 and M8 inserts so that I could bolt on P clips for gas pipe to beams that held the wall cladding.

You can get many threaded inserts from M3 upwards. I found buying a kit with multiple sizes best as I used the holes in the van where possible and this determined the bolt size. I did manage to find hex M8 inserts which was very useful as the Citroen had lots of Hex holes designed for these inserts.

Safety

There are certain regulations (legal requirements) that must be followed when converting a van to a camper van (DVLA also require certain things). There are also some caravan & Motorhome standards and trade practices, although are not legal requirements, it does make good sense to follow them as required.

Make sure you do your research and if in any doubt ask a professional. 240v AC and gas will be outside the range of many basic DIY enthusiasts and they can KILL - Be Safe and follow advice.

Personal safety seems obvious but I’ve seen enough in my working life and on YouTube to realise many people either don’t understand or choose to ignore basic safety.